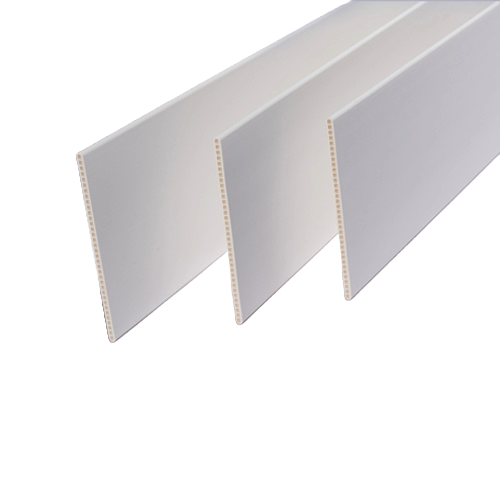

Membrane plate en céramique Solutions de filtration de précision

Membranes céramiques Al₂O₃ hautes performances avec des tailles de pores personnalisables de 30 nm à 500 nm. Conçu pour des conditions extrêmes avec une tolérance pH 2-12 et une durée de vie de 15 à 20 ans.

Sélectionnez vos exigences de filtration

Choisissez parmi notre gamme de tailles de pores conçues avec précision, chacune optimisée pour des défis de séparation et des exigences d'application spécifiques.

Directives d'application par taille de pores

30-100 nm (ultrafiltration)

- • Élimination des virus et séparation des bactéries

- • Concentration et purification des protéines

- • Élimination de la silice colloïdale

- • Élimination des endotoxines dans les applications pharmaceutiques

200-500 nm (microfiltration)

- • Élimination des matières en suspension

- • Prétraitement pour les systèmes RO

- • Clarification des flux de processus

- • Élimination des particules dans le traitement de l'eau

Propriétés matérielles supérieures

Résistance chimique extrême

La construction en céramique Al₂O₃ offre une résistance inégalée aux acides, bases et oxydants, y compris l'ozone.

Stabilité thermique

Fonctionne de manière fiable sur de larges plages de températures, permettant la désinfection à l'eau chaude et la stérilisation à la vapeur.

Durabilité mécanique

La construction robuste résiste aux fluctuations de pression, au lavage à contre-courant et au nettoyage physique sans dommage.

Spécifications techniques complètes

Propriétés physiques

Spécifications de performances

Modèles et configurations disponibles

| Modèle | Taille des pores | Taux de flux | MWCO | Application |

|---|---|---|---|---|

| WCF-MEM-030 | 30nm | 2600 LMH | 50 kDa | Virus removal |

| WCF-MEM-050 | 50nm | 2200 LMH | 100 kDa | Protein separation |

| WCF-MEM-100 | 100nm | 1800 LMH | 200 kDa | Colloid removal |

| WCF-MEM-200 | 200nm | 1200 LMH | N/A | Bacteria removal |

| WCF-MEM-500 | 500nm | 500 LMH | N/A | Particulate filtration |

Éprouvé dans tous les secteurs

Traitement de l'eau

- • Production d'eau potable

- • Traitement des eaux usées

- • Recyclage des eaux de process

Biotechnologie

- • Récolte de cellules

- • Purification des protéines

- • Clarification fermentaire

Pharmaceutique

- • Récupération d'API

- • Production WFI

- • Filtration stérile

Industrie chimique

- • Récupération du catalyseur

- • Traitement des solvants

- • Clarification du produit

Assurance qualité et certifications

ISO 9001:2015

Système de gestion de la qualité certifié pour une qualité constante des produits et une amélioration continue.

NSF/ANSI 61

Certifié pour les composants du système d’eau potable garantissant la sécurité dans les applications d’eau potable.

Tests de contrôle qualité à 100 %

Chaque membrane est soumise à des tests d'intégrité et à une vérification de la taille des pores avant expédition.

Spécifiez la bonne membrane pour votre application

Notre équipe technique vous aidera à sélectionner la taille et la configuration optimales des pores pour vos défis de séparation spécifiques. Demandez une consultation aujourd’hui.