H2O CERAspin Dynamic Ceramic Crossflow Filtration

Patent-protected rotating disc technology that eliminates membrane fouling without air scouring. Delivers bacteria-free permeate with more than 15% lower lifecycle cost compared to conventional MBR systems.

Dynamic Crossflow Filtration Principle

The unique rotating disc design creates shear forces that continuously clean the membrane surface, preventing fouling without energy-intensive air scouring.

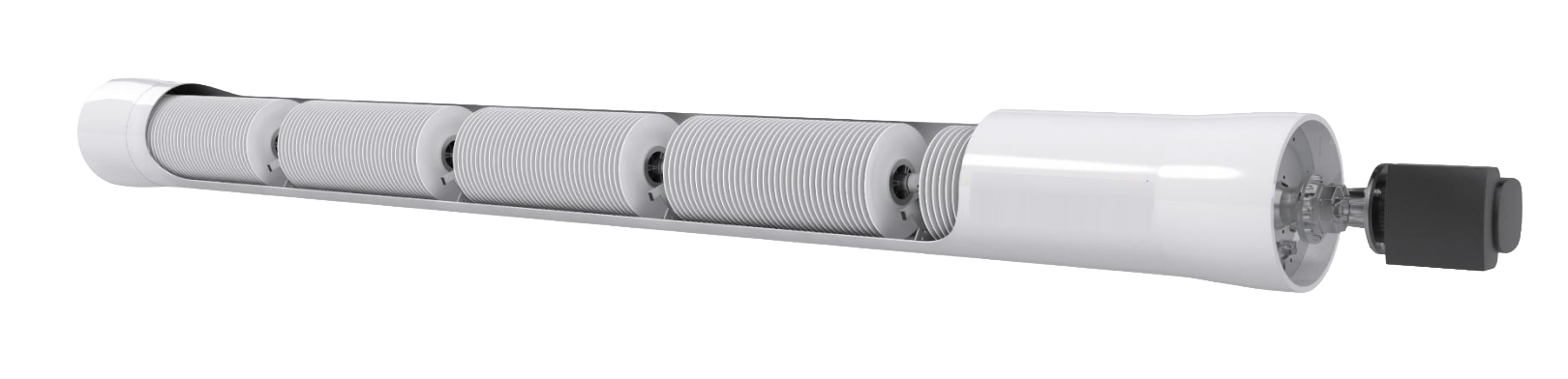

Rotating Ceramic Discs

Ceramic or polymer membrane discs rotate within pressurized fibreglass vessels, creating a dynamic filtration environment.

Wastewater Circulation

Active sludge enters the Membrane Filtration Unit (MFU) and circulates around the rotating disc wagons.

Nano/Ultrafiltration

Clean permeate passes through the membrane discs (5-200nm pore size) and is transported through hubs to the permeate shaft.

Self-Cleaning Action

The rotation creates shear forces that continuously clean the membrane surface, eliminating fouling without air scouring.

Why Choose CERAspin

No Air Scouring Required

The unique rotating principle eliminates the need for energy-intensive air scouring, significantly reducing operational costs.

Chemical Resistant Ceramic

Ceramic discs withstand harsh chemicals and aggressive CEB/CIP cleaning treatments, ensuring long operational life.

Water Reuse Ready

Produces bacteria-free, extremely high-quality permeate that is suitable for water reuse applications.

Plug & Play

Modular design with factory-tested modules for fast deployment

Remote Monitoring

Minimal onsite personnel required with remote control capability

Compact Design

Closed, space-efficient design ideal for constrained sites

Retrofit Ready

Suitable for both greenfield and retrofit installations

Technical Specifications

MFU Module Specifications

Performance Specifications

Disc Type Comparison

| Disc Type | Average Capacity | Peak Capacity | Best For |

|---|---|---|---|

| Ceramic Discs | 10 m³/h (45 gal/min) | 20 m³/h (90 gal/min) | Harsh wastewater, chemicals, high wear environments |

| Polymer Discs | 13.5 m³/h (60 gal/min) | 27 m³/h (120 gal/min) | Applications without frequent chemical cleaning |

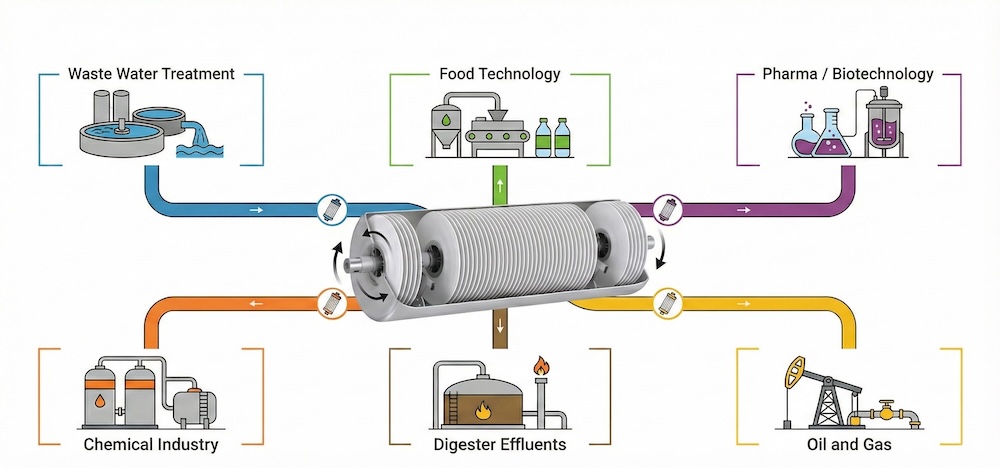

Industry Applications

Municipal Wastewater

1,500 - 5,000 Person Equivalent (PE)

- • Decentralized treatment plants

- • Water reuse applications

Food & Dairy Industry

100 - 1,000 m³/day capacity

- • Milk powder production

- • Food processing wastewater

Pharmaceutical/Biotech

High-purity permeate requirements

- • Active pharmaceutical ingredients

- • Biotech process water

Hospital Wastewater

Pathogen & pharmaceutical removal

- • Antibiotic-resistant bacteria

- • Pharmaceutical compounds

Chemical Industry

Harsh chemical environments

- • Process water treatment

- • Chemical recovery

Digester Effluents

High solids concentration

- • Biogas plants

- • Anaerobic digestion

Pilot Testing Available

We offer containerized pilot testing units to validate performance with your specific wastewater before full-scale implementation.

Pilot Container Specifications

Reference Installations

Arla Vimmerby

Sweden - Dairy Plant

Hemsedal (Ulsaak)

Norway - Municipal Retrofit

Herlev Hospital

Denmark - Hospital WW

Bjerringbro WWTP

Denmark - Full-scale Test

Ready to Transform Your Wastewater Treatment?

Contact our technical team to discuss your specific requirements and learn how CERAspin can deliver 15%+ lower lifecycle costs for your application.